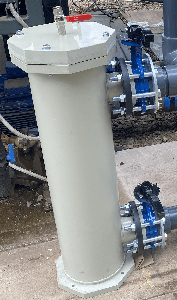

Polypropylene Filter Housing

Polypropylene Filter Housing

In some cases a Polypropylene Filter Housing is a must have requirement.

Not all applications suit a stainless steel filter housing as some chemicals are incompatible with the base metal.

We are proud to introduce our range of polypropylene filter housings fully designed and manufactured in Great Britain.

The top and bottom components are CNC machined from a solid slab of 40mm polypropylene leaving a 15mm collar the exact same diameters of the connecting pipe.

The top and bottom components are expertly butt welded to the pipe essentially fusing the housing into a single piece. Welds are scraped and cleaned back during the cooling phase for neatness.

The lid section is again machined for the external clamp holes and a groove is added to hold the sealing O ring.

The seal can be supplied in different materials such as Silicone, Viton and EPDM to suit a wide range of chemical applications.

The connection pipe holes are cut and then fused into place to form a strong bond. The backing rings are slipped on and then the flanges are added using the same jointing methods.

As each polypropylene filter housing is manufactured to order we can offer just about any combination of inlet and outlet pipe sizes and flange options.

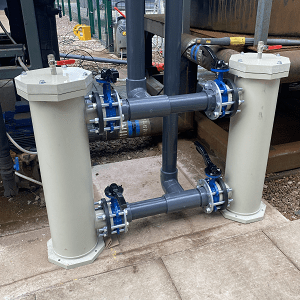

Polypropylene Filter Housing for a chilled water application.

3″ Inlet and outlet connections flanged.

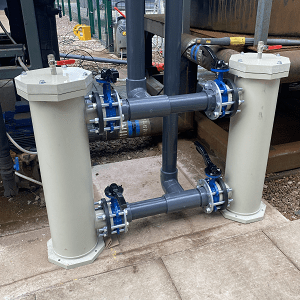

Online / Standby configuration

Type 1 Bag Filter

1/2″ Vent Valve

We attended site and installed the filters using PVC pipe to match the existing installation. The filter was added to the return before entry back into the buffer tank.

Sequential use of Bag Filters on site to clean up the chilled water starting at 400 Micron for rust and solid, slowly progressing to 50 micro for sediment cleaning.

Our polypropylene filter housings are side entry with the top discharging fluid above the bag filter and the bottom after the filter stage.

A fully welded, routed bag holder keeps the chosen Bag Filter in position.

A block device sits on top of the filter preventing it from coming out of the holder.

Lids are held in position with a choice of lever handles, screw down knobs or bolts.

Any number of lid hole configurations can be machined to your requirements.

The Polypropylene Filter Housings are supplied with a data badge and pressure tested before leaving the workshop.

We can supply pressure ratings of 6 and 10 Bar which matches the type of pipe used during manufacture.

We can manufacturer and supply single or multiple vessels and can provide a duplex kit in your choice of material.

Vessels are normally floor mounted but other options can easily be accommodated.

We have a full workshop and can provide the finished units skid mounted with a full compliment of pipe work in your chosen material complete with all valves, sensors, pockets etc.

Please contact us by email or call us +44 (0)1543 721101

Looking for a process filtration system using either stainless steel or polypropylene filter housings? Please get in touch.

Available for purchase at our online store.